As winter recedes and the promise of a vibrant boating season emerges, marinas face the important task of preparing each vessel for the adventures ahead. Offering a comprehensive spring commissioning service will ensure customer satisfaction while reinforcing your marina's reputation for excellence.

With DockMaster's comprehensive marine management system, marinas can efficiently organize, track, and execute spring commissioning for their entire fleet. The platform's purpose-built tools transform what was once a complex logistical challenge into a streamlined, systematic process that enhances staff productivity and customer satisfaction.

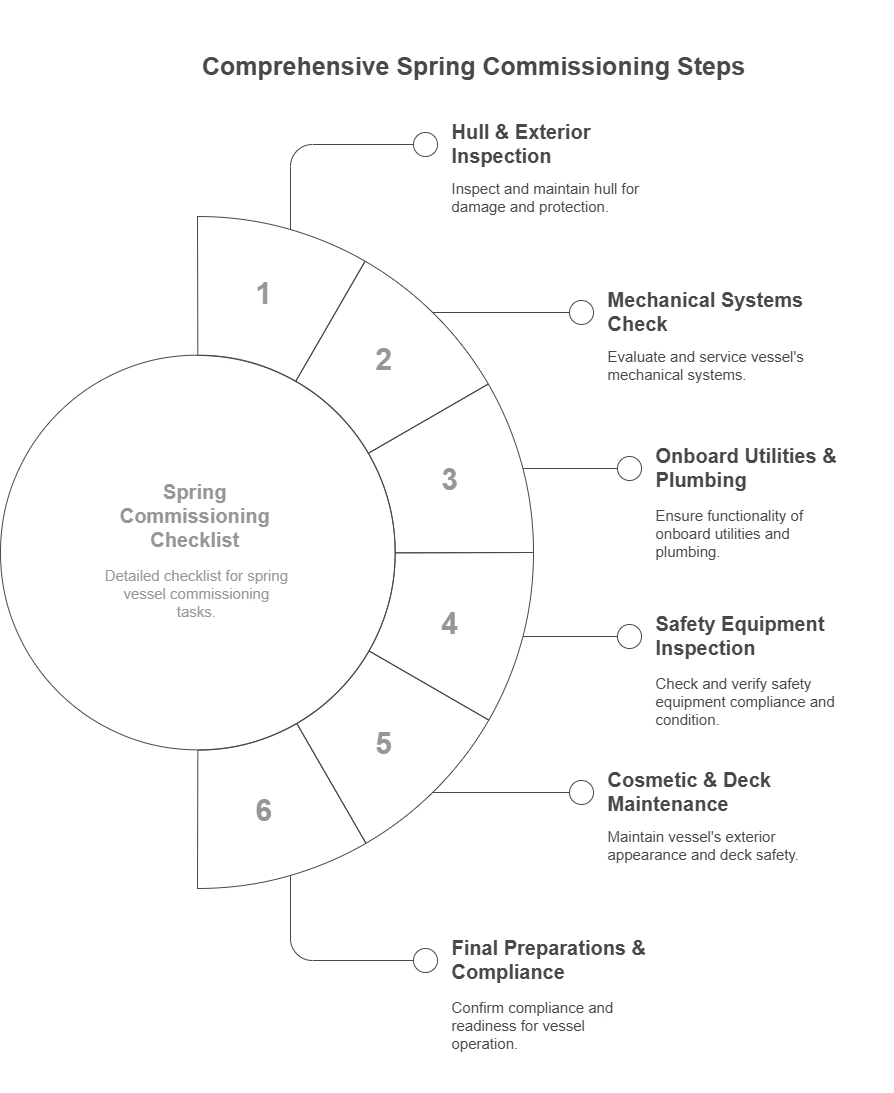

Here's a guide to the essential steps for Spring Commissioning:

Chapter 1: Hull and Exterior Inspection

A vessel's exterior is its primary defense against the elements. A thorough inspection and maintenance routine is crucial:

-

Cleaning and Waxing: Begin by washing the hull to eliminate dirt and residue accumulated during storage. Applying high-quality wax protects the gel coat from UV damage and oxidation, preserving the vessel's shine throughout the season.

-

Damage Assessment: Inspect the hull for any signs of cracks, blisters, or abrasions. Early detection of such issues allows for timely repairs, preventing further deterioration and costly fixes down the line.

-

Antifouling Paint: Evaluate the condition of the existing antifouling paint. If signs of wear are evident, repainting is essential to prevent marine growth that can impede performance and fuel efficiency.

-

Teak Maintenance: For boats featuring teak elements, clean these areas with appropriate teak cleaners and apply sealant to protect against moisture and UV damage, ensuring longevity and aesthetic appeal.

-

Hardware Inspection: Examine all railings, cleats, and fittings to ensure they are secure and free from corrosion. Tighten any loose components and replace corroded hardware to maintain safety and functionality.

The vessel's appearance and its structural integrity are enhanced by meticulously attending to the hull and exterior, setting the stage for a trouble-free season.

DockMaster Integration: Track hull inspections, waxing services, and exterior repairs in DockMaster's detailed service module. Document all findings with attachments for before/after photos, ensuring transparent communication with boat owners while maintaining comprehensive vessel records for future reference.

Chapter 2: Engine and Mechanical Systems

The reliability of a vessel heavily depends on its mechanical systems. A detailed inspection ensures optimal performance:

-

Engine Maintenance: Replace engine oil and filters to eliminate contaminants. Inspect belts and hoses for signs of wear, cracks, or stiffness, replacing any compromised components to prevent failures. Ensure the cooling system is flushed and filled with the appropriate coolant mixture.

-

Fuel System: Check fuel lines for leaks, brittleness, or softness, and ensure all connections are secure. Replace any damaged lines to prevent hazardous situations. Inspect fuel filters and replace them to maintain fuel purity and engine efficiency.

-

Battery Care: Test each battery's voltage and capacity. Clean terminals to ensure good electrical contact and apply a corrosion inhibitor. Verify that batteries are securely mounted to withstand vessel movements.

-

Bilge Pumps: Operate bilge pumps to confirm they are functioning correctly. Clean any debris from the bilge area that could obstruct pump operation. Test automatic float switches to ensure they activate the pump as intended.

-

Propeller Examination: Inspect propellers for damage such as dings, bends, or pitting. Ensure cotter pins are intact and that propellers are securely fastened. Addressing propeller issues enhances fuel efficiency and reduces strain on the engine.

-

Steering and Controls: Test the steering system for smooth operation and check for any signs of stiffness or leaks in hydraulic systems. Ensure throttle and shift controls move freely and return to neutral positions without resistance.

Proactively servicing the engine and mechanical components minimizes the risk of in-season breakdowns, ensuring a safe experience for boaters.

DockMaster Integration: Schedule recurring maintenance tasks through DockMaster's preventive maintenance system. Technicians can access complete service histories, document all mechanical work performed, and automatically generate parts requisitions, ensuring that engine maintenance is thorough, tracked, and efficiently executed.

Chapter 3: Plumbing and Electrical Systems

Ensuring the functionality of onboard systems is vital for safety and comfort:

-

Freshwater Systems: Thoroughly flush and sanitize freshwater tanks to eliminate bacteria and odors. Inspect all hoses and connections for leaks or signs of wear, replacing any compromised parts. Test faucets, showers, and pumps to confirm proper operation.

-

Sanitation Systems: Examine the head and holding tanks for leaks or blockages. Ensure that seals and gaskets are intact to prevent unpleasant odors. Operate macerator pumps and verify that overboard discharge systems comply with local regulations.

-

Electrical Systems: Test all onboard lighting, including navigation and interior lights, replacing any faulty bulbs. Inspect wiring for signs of chafing, corrosion, or loose connections, addressing any issues found. Verify the operation of electronic equipment such as GPS, radios, and depth finders.

-

Shore Power: Examine shore power cables for wear, burns, or corrosion at both ends. Test ground-fault protection devices to ensure they function correctly, reducing the risk of electrical hazards.

-

Safety Alarms: Test smoke detectors, carbon monoxide alarms, and bilge alarms to ensure they are operational. Replace batteries as necessary and confirm that all safety devices are within their service life.

Attending to the plumbing and electrical systems not only enhances the comfort of those aboard but also plays a critical role in ensuring safety during voyages.

DockMaster Integration: Create detailed checklists within DockMaster to ensure no plumbing or electrical inspection point is missed. Technicians can document findings directly in the system, automatically flagging critical issues for immediate attention and generating work orders for necessary repairs.

Chapter 4: Safety Equipment Inspection

Safety is the cornerstone of any boating adventure. A meticulous review of all safety equipment ensures compliance with regulations and, more importantly, the well-being of all aboard.

-

Personal Flotation Devices (PFDs): Verify that each vessel has an adequate number of U.S. Coast Guard-approved life jackets in good condition. Ensure they are accessible and appropriately sized for potential occupants.

-

Visual and Audible Signals: Inspect flares for expiration dates and functionality. Test air horns or other sound-producing devices to confirm they operate effectively.

-

Fire Extinguishers: Examine fire extinguishers to ensure they are fully charged, properly mounted, and within their service dates. Replace or service any that do not meet these criteria.

-

First Aid Kits: Assess the completeness of first aid kits, replenishing any used or expired items. Store them in a dry, accessible location.

-

Emergency Position Indicating Radio Beacons (EPIRBs): Test EPIRBs according to manufacturer instructions, verifying battery life and signal transmission.

-

Navigation Lights: Confirm that all navigation lights are operational and lenses are clean, ensuring visibility during low-light conditions.

-

Bilge Pumps and Alarms: Test bilge pumps for proper operation and verify that bilge alarms are functional, alerting crew to unwanted water ingress.

Marinas uphold the highest standards of preparedness if they systematically inspect and maintain safety equipment, fostering trust and confidence among boaters.

DockMaster Integration: Maintain precise records of safety equipment inspections and certifications through DockMaster's compliance tracking features. The system can automatically alert staff to upcoming expiration dates for items like flares and fire extinguishers, ensuring vessels maintain full regulatory compliance.

Chapter 5: Cosmetic Maintenance and Detailing

A vessel's appearance reflects its overall care and can significantly influence client satisfaction. Attention to cosmetic details not only enhances aesthetic appeal but also contributes to the vessel's longevity.

-

Hull Cleaning and Polishing: Beyond the initial wash, employ specialized cleaners to remove stains or oxidation. Apply a high-quality polish to protect the hull's surface and enhance its shine.

-

Deck Maintenance: Clean non-skid surfaces to remove dirt and mildew, ensuring safety underfoot. Treat wooden decks with appropriate oils or sealants to preserve their condition.

-

Canvas and Upholstery Care: Inspect canvas covers, biminis, and enclosures for tears or wear. Clean and apply water-repellent treatments as needed. For upholstery, use suitable cleaners to remove stains and protect against UV damage.

-

Metal and Brightwork Polishing: Polish stainless steel and chrome fittings to prevent corrosion and maintain their luster. Address any signs of pitting or rust promptly.

-

Window and Hatch Maintenance: Clean windows and hatches, checking seals and gaskets for leaks. Lubricate moving parts to ensure smooth operation.

Regular cosmetic maintenance elevates the vessel's visual appeal and serves as a preventive measure against wear and environmental damage.

DockMaster Integration: Manage detailing appointments and track cosmetic maintenance through DockMaster's scheduling system, optimizing staff allocation and ensuring consistent service quality. Document before/after conditions with photo attachments, providing visual evidence of work completed.

Chapter 6: Final Preparations and Launch Readiness

As the culmination of the commissioning process approaches, final checks ensure that each vessel is truly ready for the water.

-

Documentation and Compliance: Verify that all registration, insurance, and inspection documents are current and onboard. Ensure that vessels comply with local and federal regulations.

-

Fuel System Checks: Top off fuel tanks, inspect for leaks, and replace any degraded fuel lines or fittings. Ensure that fuel shut-off valves are operational.

-

Seacock Operation: Open and close all seacocks to confirm they move freely and seal properly. Lubricate as necessary to prevent seizing.

-

Load Testing: Simulate typical load conditions to assess the vessel's performance and stability. Address any issues that arise during these tests.

-

Client Communication: Provide clients with a detailed report of the commissioning process, highlighting any areas of concern and actions taken. Offer recommendations for ongoing maintenance and care.

By meticulously attending to these final preparations, marinas ensure that vessels are not only seaworthy but also primed to deliver exceptional experiences on the water.

DockMaster Integration: Generate comprehensive commissioning reports for boat owners directly from DockMaster, detailing all work performed and recommendations for future maintenance. The platform's customer portal allows boat owners to review their vessel's status and approve any additional recommended work, streamlining the final stages of the commissioning process.

Key Takeaways:

-

A complete spring commissioning encompasses safety inspections, cosmetic maintenance, and thorough final preparations.

-

Diligent attention to each aspect of the vessel enhances safety, performance, and client satisfaction.

-

Clear communication with clients about the commissioning process fosters trust and underscores the marina's commitment to excellence.

-

DockMaster's integrated marina management software transforms spring commissioning from a complex logistical challenge into a streamlined, systematic process that enhances staff productivity and customer satisfaction.

By embracing this holistic approach to spring commissioning, marinas will uphold the highest standards of service while cultivating enduring relationships with their clientele, setting the stage for a successful and enjoyable boating season.